Flow monitor FLUOMAC® Automatic-Controller unwired

In stock

for orders worth €100 or more (DE)

10€ discount

20€ discount

Mon. to Fri. from 10:00 to 16:00

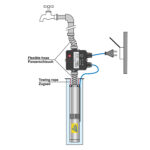

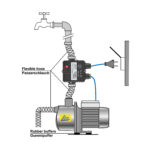

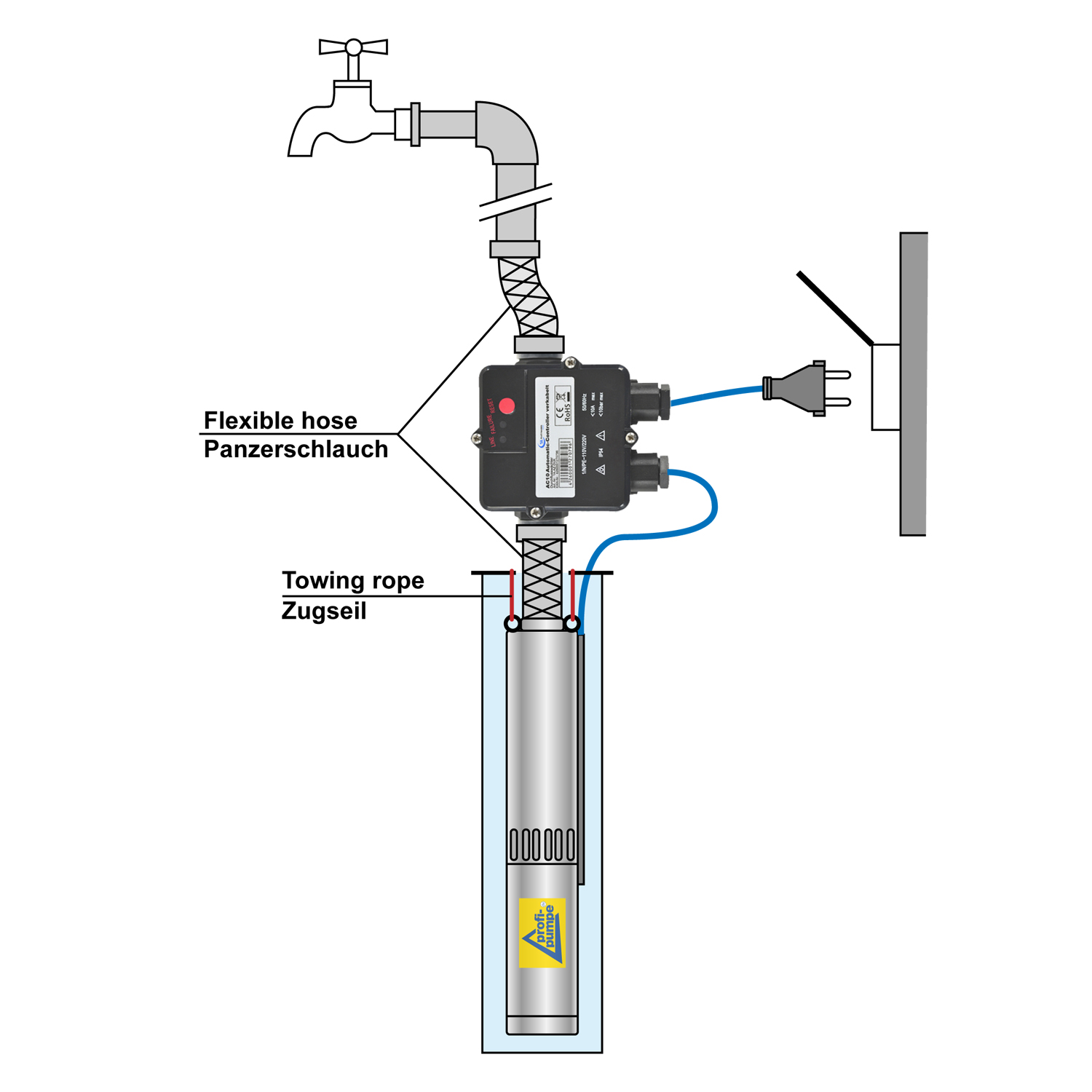

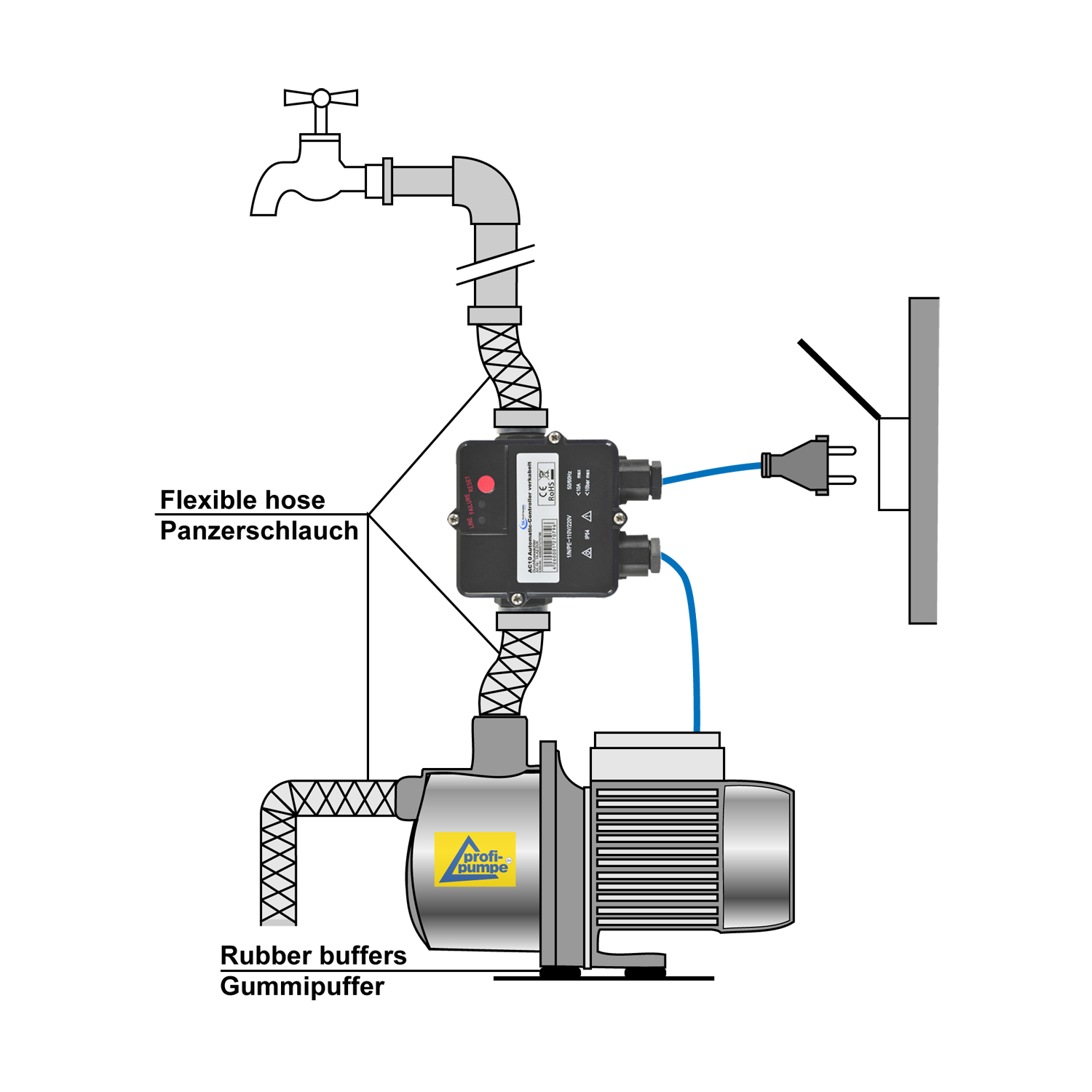

- Pressure/flow-controlled, automatic activation of submersible and centrifugal pumps

The Flow monitor automates and controls the switching on of the centrifugal or submersible pump. It monitors the pressure in the pipe system from the pump to the consumer. When water is drawn from the pipe system, the pressure decreases. If the pressure falls below 1.5 bar (adjustable) the flow monitor switches on the connected device (e.g. centrifugal pump). This supplies the consumer with water again. If the consumer is closed, the flow rate is reduced and the pump is switched off.

The special feature of this flow monitor is the Built-in dry-running protection. If there is no water (cistern empty) after switching on the pump, the flow monitor switches the pump on again automatically off (dry-running protection).

A Non-return valve is also integrated in the flow monitor. This prevents the pipe system on the consumer side from running empty.

The maximum operating pressure of this pressure switch is 10 bar. The switch-on pressure is adjustable (1 - 3.5 bar).

Our tips

With the use of any pump switchgear, we strongly recommend in front of the switchgear is always an effective Pump pre-filter/cartridge filter to be used. This significantly reduces problems caused by water contamination. All commercially available professional switching devices have a non-return valve on the inlet side. If a grain of dirt settles between the sealing surfaces, the switchgear will no longer function properly. The flow monitors already contain a non-return valve; no additional non-return valve must be fitted between the pump and the flow monitor as this can lead to faults and even damage to the pump.

Many good reasons why you should buy this product:

- Integrated dry-running protection

- Built-in non-return valve

- Automation of pump control regulated by pressure and flow rate

- Easy to handle

- Protecting the pump

Technische Unterlagen

Service-Anliegen

- Transportschaden melden

- Servicebogen für Dieselpumpen

- Troubleshooting - Hilfe zur Fehlerbehebung

- Revocation

- Retourenablauf

Wir bearbeiten die Retouren nicht unter unserer Büroadresse, sondern in unseren Service-Centern:

Regentonnen, Regenfilter, Gartenbrunnen, Airbrush an:

1A profi-pumpe.de UG (limited liability)

Service & Lager

Hilderser Str. 11

D-98590 Schwallungen

Deutschland

Alle restlichen Produkte an:

1A profi-pumpe.de UG (limited liability)

Service & Lager

Budenheimer Weg 55

D-55262 Ingelheim

Deutschland

Leave a Reply

You must be logged in to post a comment.